Paint Shaker vs. Vortex Mixer: Which is the Right Choice for Your Materials?

Two of the very common motions when mixing materials such as paint are the vortex motion and shaking. Each motion has its pros and cons, and each motion results in a different machine design with varying costs, ergonomics, and benefits. One motion allows mixing many cans and the other motion is faster for single cans. How do we determine the right machine and motion for a specific store, budget, customer base, and the materials being mixed?

Why is Mixing Needed?

If a can of paint is tinted but not mixed, painting will result in ugly, bold, multicolor blotches. Before mixing, there are 3 layers in the can: (1) base – usually white, (2) many colors of tint, and (3) air. However, mixing is difficult because the can will have nooks and crannies where the tint gathers. Tint and base paint are harder to clean from the area at the bottom corner of the can, the grooves around the lid, and other tight areas. This is true for all sizes of cans.

Vortex Mixing & Mixing Machines

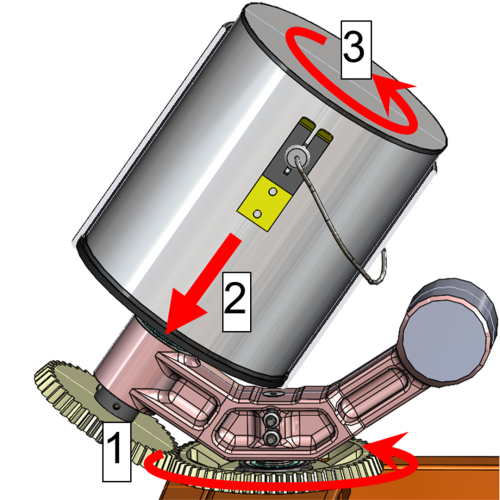

There are 2 primary motions involved in vortex mixing. Initially, the can is tilted when it is inserted into the mixer so that when it starts spinning (1), the can will be held in place by centrifugal force (2). The 2nd motion causes the can to spin on its axis (3) to create the tornado-shaped vortex. The tilt, speed, and the ratio of the two motions all affect mixing.

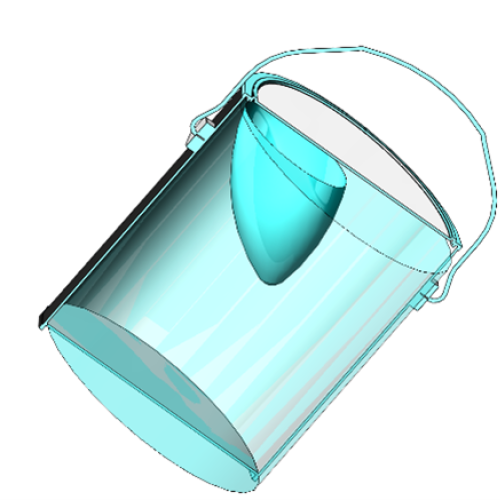

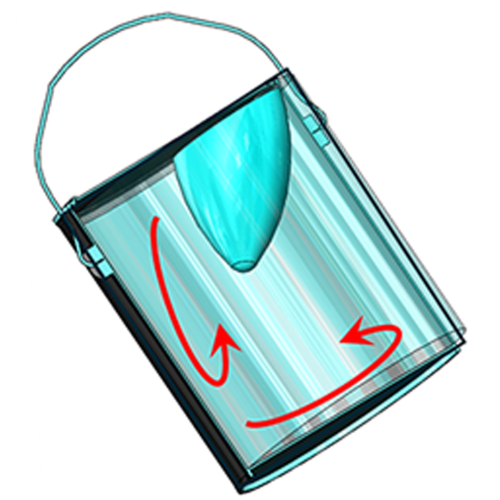

The shape between the air and liquid is what gives the vortex motion its name, since it resembles the vortex in a tornado. In the cutaway picture showing the paint inside a can, you can see a computer simulation (computational fluid dynamics) of the vortex shape in a 1-gallon can in the Radia Speed Demon mixer.

The liquid in the paint cans both rotates around the can center and moves the tint from the top of the can to the bottom of the can and back. These two motions stretch out the layer of tint and fold it into the base paint, much like a baker kneads dough.

Unlike dough, paint can be mixed correctly or incorrectly. If done poorly, this motion could pull air into the liquid and cause foaming. Designed correctly, air in the liquid can be forced out to give a smooth, air-free mixture. The analytical and experimental approaches used by Radia maximized the advantages of this motion to give smooth, creamy paint that looks great on a wall. This can also result in a good mix for epoxy or many other materials as well.

The can holder in the mixer is designed for easy loading and unloading of a 1-gallon can. The can is simply dropped in, and the handle is held upright to make it easy to take out after mixing. The vortex mixer supplied by Radia is built for a 1-gallon can, but if a smaller can needs to be mixed, an adapter is available.

The Speed Demon mixer is exceptionally quiet, which surprisingly led to customer complaints in earlier versions of the machine! Customers could not tell when the mixer was done mixing due to the background noise in the store. In response, Radia added a bright LED to show when the machine was mixing and when the mix was complete.

Agitation Mixing & Mixing Machines

There are 2 motions involved in a shaker-style mixer. The first motion (1) is up and down. The 2nd motion (2) is an oval motion at the bottom. The up-down motion creates mixing through the body of the paint and especially at the top of the paint. The oval motion at the base caused the paint to roll over (3) and brings the paint from the less mixed location at the bottom to the better mixing area at the top.

This mixing motion is more violent and chaotic than the vortex motion, which can be either good or bad. The turbulence at the top is very good at removing tint from the nooks and crannies at the top of the can. However, it may introduce some air, but this is rarely an issue.

One of the primary advantages of the Agitar shaker is that it automatically clamps onto the can or cans placed in the mixer. If a can has not been fully sealed, this clamping action can prevent paint spills. Mixing multiple cans of the same size at once is possible, as well as mixing cans of different heights. The Agitar can mix 5-gallon or taller cans down to pint-size cans.

One of the disadvantages of the clamping action is that very thin-walled cans and some plastic square cans could be damaged. This is due to the tradeoff of needing a high clamp force to run at a speed that quickly mixes the content of the can. A standard round metal or plastic can of any size is perfect for this type of mixer. For some weaker cans, an adapter is available that takes the crush force but allows enough compression to hold the cans in place.

Factors to Consider When Selecting a Shaking or Vortex Paint Mixing System

Selecting mixing equipment involves a number of important factors to consider to find the best fit for the application.

If a mixer must handle many sizes of cans, then the Agitar shaker may be a better fit. It has an exceptionally large range and can mix cans as large as a 5-gallon or even larger down to cans as small as a pint. However, the Speed Demon vortex mixer does have adapters that can hold pints, quarts, and other cans that are smaller than one gallon.

How many cans of the same size are there in a typical order? In the Agitar, four one-gallon containers of the same height can be mixed at once. Also, multiple smaller cans of the same height and type can be mixed.

Cost and footprint favor the Speed Demon. Depending on the layout, it might be possible to put the smaller vortex mixer under a shelf.

Radia also offers a table designed to fit 2 to 4 speed demon mixers. It places them at an ideal ergonomic height that reduces operator reach and movement while minimizing the footprint for the table/mixer combination. The Auto Lid Press on the table assures a good seal on the lid.

The quietest mixer is the Speed Demon. Often, against the background noise, it is difficult to tell if it is running without looking at the LED indicator.

Both mixers are fast and effective at mixing paint or other custom materials such as epoxies. Radia has responded to the trends toward lower VOC paints that are harder to mix by testing and improving mixing. Radia also offers testing of unusual materials whose mixing characteristics are unknown. A customer can verify before a purchase that they have an effective mixer and the correct mixer for the application. Even if a container does not fit in the mixer, a custom adapter can often be created to hold it in place.

All Radia mixers have undergone extensive life cycle testing and are designed to last many years or even decades of use. Radia customer service is still servicing machines that were discontinued well over a decade ago. Occasionally, Radia (previously named Red Devil Equipment) still runs across machines built before any of the employees at Radia were born!